EL FIAD Agricultural system is designed for managing work in agricultural companies that have farms, packinghouse and products for exportation (packed cartoon) to their customers all over the world.

For this goal, we established ,this system with 3 cycles to achieve the goal ....

ِAddition to.....

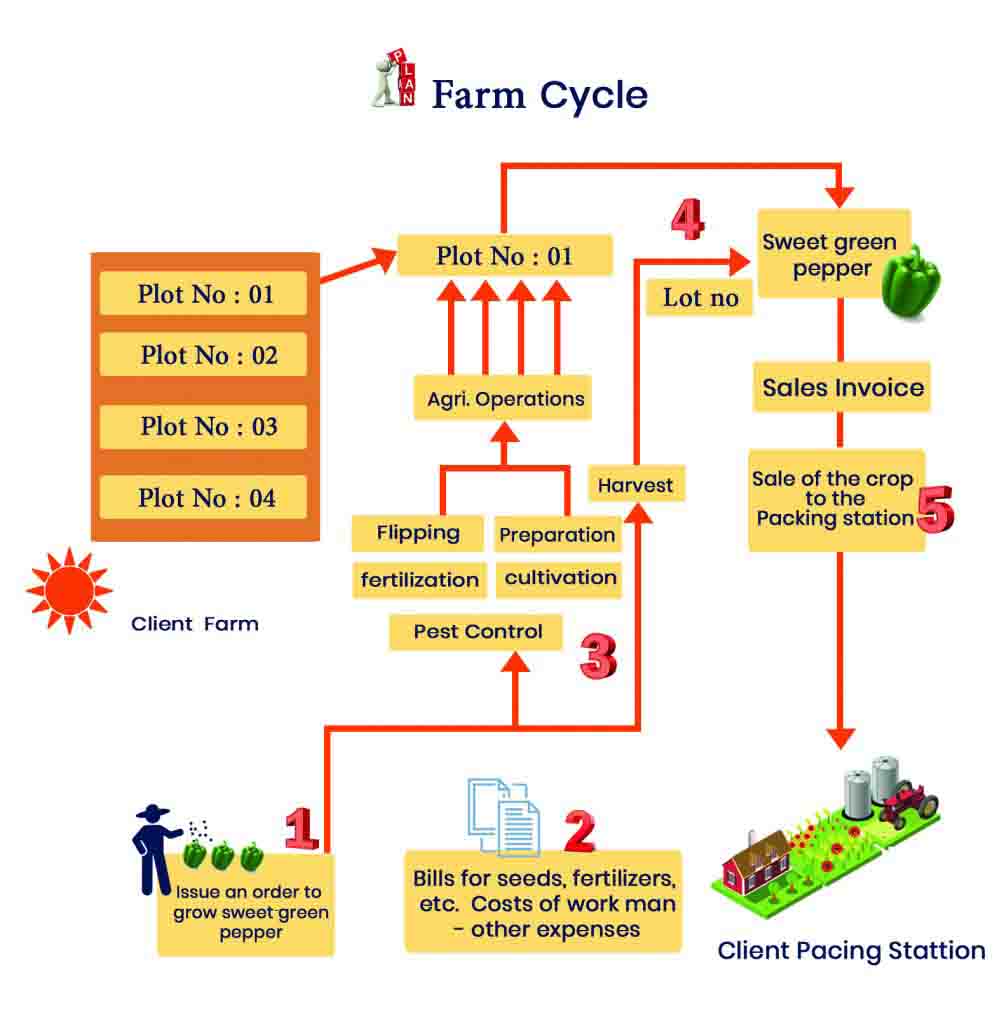

1-Farm Cycle:

Starting from preparing an agricultural plan based on the sales plan , which is prepared before the beginning of the agricultural season.

The system includes everything happenning in farm starting with :-

- Splitting the farm's land into sections which are called PLOTS, every plot has a specific area

- Determine the kind of agriculture (tunnels - greenhouses - ……etc.),and the kind of crop

- Follow up the agricultural cycle and operations for every PLOT (Seedling, irrigation, harvesting, clipping grass…..etc. ).

- follow-up the cost of purchasing seeds and fertilizers from suppliers, cost of operations accomplished in the farm through season ,down to final product in each PLOT ( Quantity and value)

- After harvesting we get final product ,issuing LOT_NO for every crop ,the LOT_NO is a unique code to trace the product in this stage.

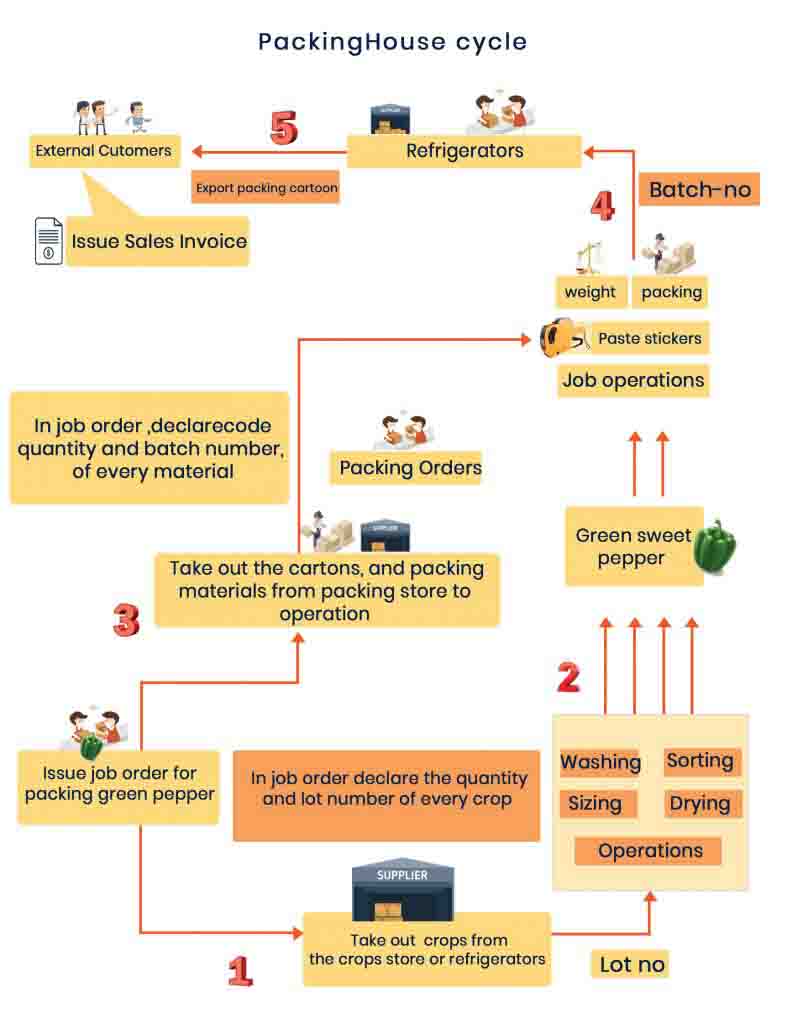

2-Packinghouse Cycle

Starting from purchasing the crops from the client's farm or the other ( Suppliers), and transferring

them to the station for packing in cartoons .

- Issued Job Orders for packing.

- Follow up all processes happened through operation (sorting - washing - drying - scanning - scaling - filling - weight - paste stickers ... etc.).

- Issue Batch_NO number, Batch_NO Is a unique code to trace the product through packing house operation.

- Finally we make a final product ( packed carton).

- The system calculates precisely the cost of product carried with all different cost elements(direct and indirect costs ) .

- Barcode consists of (Lot_no+Batch_no) , as a sticker on every cartoon.

- Preparing every customer's request by collectting cartoons in bales for export.

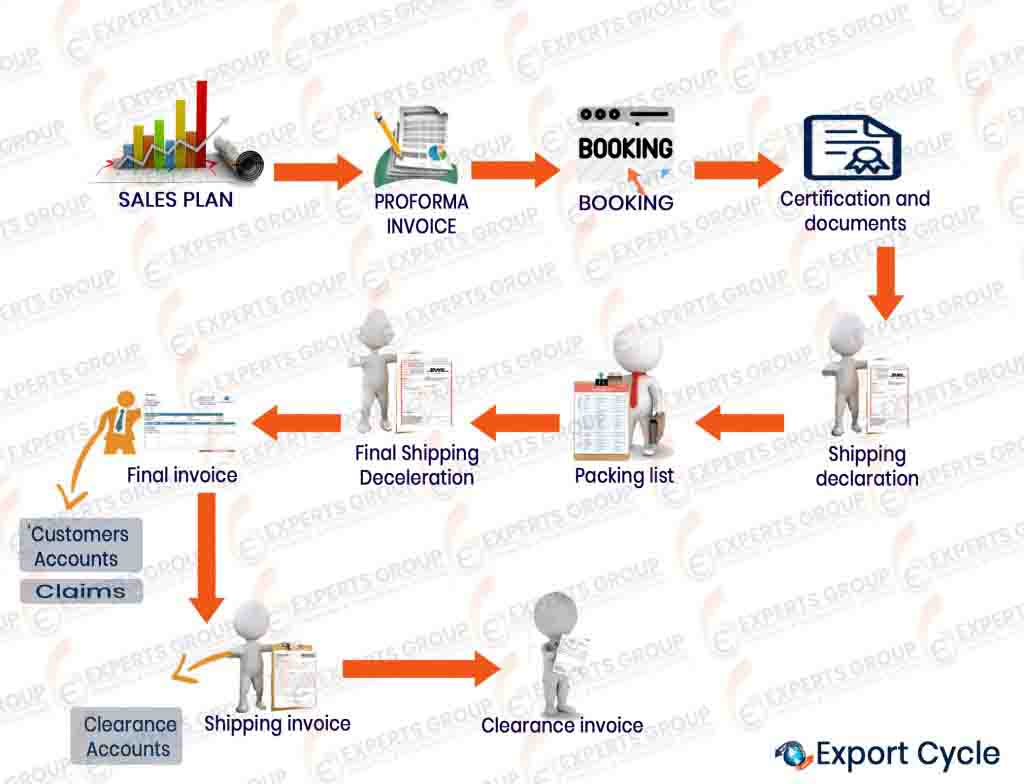

Export Cycle

After preparing the final product the export department starts to execute all procedures to export the final product starting with :-

Quality Control

You can record all tests and analysis for quality.

- Elements analysis (compost - soil - water)

- Pesticides analysis( Heavy Metals - Microbiology)

To ensure the safety of the product from its cultivation up the arrival of the external client.

System is preparing a Request for Certificate of Control for products sold outside the European Union, and for the export of organic products Into the European Union.

Traceability

Traceability Problem Solution

What happens when the external customer informs the exporter that there is a problem in the product? There will be 2 problems which might/should be occured

- Pesticide Problem

- In this case, the system searches for the LOT_NO ( it already exists in the sticker on the cartoon ) The system shows a full report (Lot_no History) to make sure that the lot number belongs to his farm or whether a certain crop has been denied by one of the suppliers of the agricultural crops .

- In the case in which the crop from his farm, the system produces a report showing all the agricultural operations carried out on the agricultural section especially protection processes in terms of the quality of the pesticide sprayed, the date of the operation and the safety period. The system also extracts a report showing all of the analyzes (eg: the Center for Agricultural Research, the Central Technology Laboratory, or any other external center). The report shows the date of the samples and the results of the analysis conducted on the agricultural section. In the case of the negative results, the report is sent to the external client to prove that there is no problem.

- Quality Problem

- By searching for the Batch_no number on the customer's carton ,the system will show a complete report (Batch_no History) to insure that the Batch_No belongs to the company and not another company, the report will be showing the order number (the packing order) , when that is accomplished , the production line and the responsible supervisor of the production line , the employees who have performed the different operations.

- The problem may not be related to the production cycle, but the problem may have occurred with the shipping company that shipped the goods to the customer under bad circumstances , it did not abide with the right conditions for the shipping of the products through the trip (Shipping Conditions), which are noted through the shipping request (Shipping Declaration) such as temperature and humidity.

The shipping company is responsible for this problem and Punitive procedures must be taken with.